Table of Gemstones Hardness, S.G., R.I.

Hardness is the resistance a gemstone or other material offers to scratching or abrasion. To the public (and, unfortunately, too many jewelers) hardness is the means by which gemstones are identified. Actually, the value of hardness to the gemologist is strictly limited. The information gained by this test is often of doubtful value, and the danger of defacing or even breaking a valuable stone is much too great to permit its indiscriminate use in gem testing.

The basic idea of hardness is that a harder stone will scratch a softer one, if a sharp point or an edge of the harder material is drawn across the softer one. Thus diamond scratches ruby, ruby scratches topaz, topaz scratches quartz, etc. Hardness is related to the strength of the bonds between the atoms in a stone. If the bonds are relatively strong, the stone is relatively difficult to scratch because of the resistance it offers to the tearing out of large numbers of atoms by the hardness point.

A gemstone may be very hard but comparatively fragile. If struck

a sharp blow parallel to a direction of weakness, even a diamond will

cleave readily. More fragile gemstones, such as emerald or zircon, may

fracture without receiving violent blows. Zircon and emerald are hard,

but they are low in a scale of relative toughness, thus hardness has

to do only with resistance to scratching, not with resistance to breakage.

Degrees of Hardness

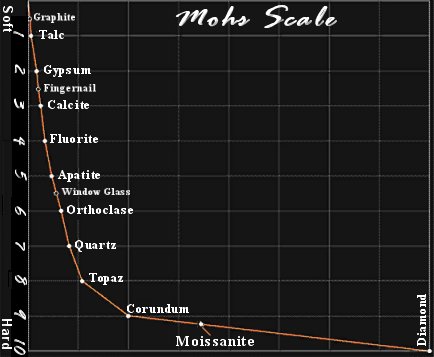

Many years ago Mohs, a German mineralogist, proposed a table that

is still known and referred to as MOHS' SCALE OF HARDNESS, which is:

| Gemstone | Hardness |

|---|---|

| Talc | 1 |

| Gypsum | 2 |

| Calcite | 3 |

| Fluorite | 4 |

| Apatite | 5 |

| Orthoclase | 6 |

| Quartz | 7 |

| Topaz | 8 |

| Corundum | 9 |

| Diamond | 10 |

This scale has been the source of great misunderstanding in the jewelry business and has caused much false information to be given to customers. It is NOT a scale in which the numbers indicate equal divisions of hardness, such as the divisions of inches on a ruler indicate equal divisions of distance. The intervals of hardness between these numbers are NOT EQUAL. The scale means that ORDINARILY a mineral of hardness 9 will scratch a mineral of hardness 8, that one of 7 will scratch one of 6, etc. Likewise, two substances of the same hardness will scratch each other equally well. This scale is valuable when testing the RELATIVE hardness of gem materials. The accompanying table Shows the relative hardness of the common gem minerals and related substances and lists average values; most of these materials, however, very slightly from the average values shown.

Mohs' scale might easily confuse the jeweler as well as the public.

Actual grinding tests have resulted in statements that diamond is 90

times harder than corundum (ruby and sapphire), that corundum is at

least five times harder than topaz, and that topaz and quartz show but

little difference in hardness.

More reliable tests conducted at the National Bureau of Standards with

a Knoop indentor hardness tester have shown that diamond has an indentation

hardness of about five times that of corundum. Results of these tests

have shown that if the top four minerals of Mohs' scale were listed

on a true comparative basis, they would have the following values: diamond

46, corundum 9, topaz 8, and quartz 7.

Variations in Hardness

Careful tests reveal that the hardness of any crystal substance may vary on different crystal faces. Even the same face of a crystal may show a difference in hardness when scratched in different directions. This might be compared with a piece of wood that shows a different hardness with the grain and against the grain. All cutters recognize the greater hardness of a diamond crystal parallel to the octahedral face, as compared with the hardness in any other direction. It is important to remember that a cut stone may show a variation in hardness on different facets and in different directions on the same facet. Slight variations in the hardness of different varieties of the same species are also found. For example, emerald is near 7 1/2 on Mohs' scale and aquamarine i.e. 8, although both are beryl.

Limitations of Hardness

Before considering the application of hardness tests to gem identification, it is essential to make clear their relative value. Hardness tests were useful in the days before optical tests were developed to their present high degree of accuracy. Although hardness still has some limited uses in gem identification, for the most part it has been replaced with more positive methods that cannot possibly harm a stone. Thus hardness tests are taboo for the identification of faceted stones. However, they still have some limited uses when testing an occasional opaque gemstone and in the testing of rough material.

An interesting use of hardness points or a steel file on a faceted stone is that employed by some, pawnbrokers when they suspect a customer of trying to pass off an imitation as a diamond: They attempt to place an obvious scratch across the table of the stone to protect less observant members of the pawnbroker’s fraternity. Obviously, this is a dangerous practice, for a genuine stone may be cleaved; or if the customer has made an honest mistake, serious consequences are probable. This, however, is an unusual use for hardness.

The major reason for this discussion of hardness is to point out

the relative wear resistance of the important gemstones. Secondary reasons

relate to dispelling misconceptions about hardness, and to indicate

how hardness plates and points may be used in the testing of rough gemstones

and opaque's.

The danger of testing transparent stones by hardness cannot be over-emphasized.

Jewelers frequently send to one of the laboratories stones belonging

to customers on which hardness tests have been made, with the result

that re-cutting was mandatory. In no case was a hardness test of value

in identifying these stones. As an illustration of the insignificant

and decreasing use of hardness in testing, the laboratories annually

test thousands of transparent stones without ever resorting to a hardness

test. On opaque pieces, such as badly worn or poorly polished cabochons,

hardness tests are used on occasion. Unfortunately, hardness tests are

used frequently by poorly equipped geologists with a smattering of mineralogy.

The laboratories have tested many stones supposedly tested by government

or university scientists as over 9 in hardness (and thus presumably

diamonds) that were actually quartz. The harder the stone and the smoother

the surface, the more likely are over-estimates of hardness.

Tests For Relative Hardness

The object of hardness tests is to determine what mineral on Mohs'

scale is most nearly equal to the hardness of the gemstone being tested.

Any gemstone that, is approximately the hardness of quartz (7) is said

to be 7 in hardness, but if it tests between two of the minerals on

the scale, it is expressed by 1/2. Thus a gemstone that tests harder

than quartz but softer than topaz is said to be 7 1/2 in hardness.

In addition to Mohs' scale, it is well to known that tests of relative

hardness can be made by the following objects, which have the individual

hardness values shown:

| Fingernail | 2 ½ or under |

| Copper coin | 3 |

| Steel file | 6 to 7 |

| Knife blade | 5 ½ or under |

| Window Glass | 5 ½ or under |

HARDNESS POINTS are merely metal stems on the ends of which have been mounted small crystals or fragments of minerals. The materials most commonly used are carborundum (9 1/4), corundum (9), topaz (8), quartz (7), and feldspar (6). When testing with hardness points or a steel file, the point of the instrument should be applied to the back of the stone with a very firm but fairly light pressure. Be sure that the stone is held in such a way that there is no danger of breaking it. Many opaque cabochons are very flat; therefore, if such a stone is held between the fingers and the point applied to the centre of the back the resultant stress may cause it to split. It is obvious that the point should be applied to the back rather than the top, for even an unnecessarily large scratch will not be visible when the stone is mounted. But it is wise to apply the point at a place where the finger is supporting the stone. In addition, it should not be close enough to the edge to cause chipping when the point is applied.

The hardness point should be held erect and more or less perpendicular to the surface being tested in order to avoid the danger of breaking the point. The point is then drawn across the surface very carefully for a distance of only about 1/32 to 1/16 of an inch. The feel of a file or hardness point as it “bites” into a softer substance or slides over a harder surface soon becomes familiar, as does the sound of each.

Either file: or point often leaves a STREAK of itself on a slightly rough surface. To distinguish between a streak and a scratch, rub the surface and examine it with a loupe. A scratch will form a depression that is still evident after the powder has been rubbed away. The term streak also refers to the powder left by a mineral when drawn across rough porcelain, the color of which may be characteristic for that mineral. For example, the red brown color of the hematite streak provides a means of separating this mineral from its numerous substitutes.

HARDNESS PLATES are sometimes used instead of points for testing. These plates are merely polished sections of the minerals of Mohs' scale. The stone to be tested is pressed firmly against the plate and moved about 1/16 of an inch. The plate is then observed to determine whether a scratch was made. Obviously, hardness plates are less likely to injure a stone than the points. However, if hardness plates are used without care the girdle of the stone may be damaged. A short time ago a student sent a fine tourmaline to the LAB that he had tested on a hardness plate. The damage to the girdle was sufficient to require re-cutting the entire stone. Hardness plates with sharp corners are sometimes used in place of hardness points.